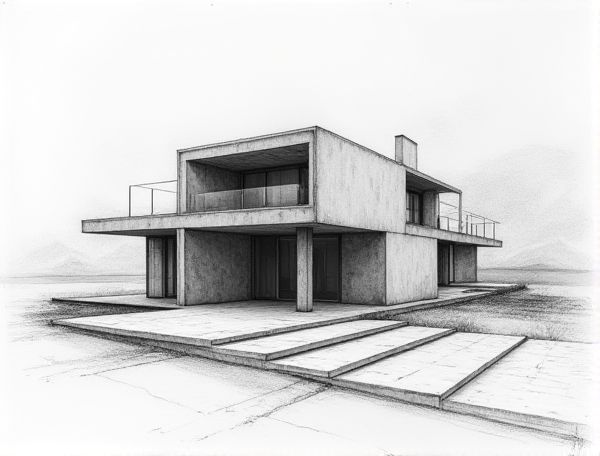

Photo illustration: Parametric home design with 3D-printed concrete elements

Parametric home design integrates advanced algorithms to create highly customizable architectural forms, utilizing 3D-printed concrete elements to enhance structural efficiency and aesthetic precision. Explore how You can transform your living space by embracing this innovative technology in the full article.

Introduction to Parametric Home Design

Parametric home design leverages algorithms and computational processes to create dynamic, customizable architectural plans that adapt to specific environmental and user needs. This approach utilizes parametric modeling software to manipulate design variables, resulting in innovative spatial configurations and optimized material efficiency. By integrating data-driven parameters, parametric home design enhances aesthetic flexibility and sustainability in modern residential architecture.

The Rise of 3D-Printed Concrete in Architecture

3D-printed concrete revolutionizes home designing by enabling intricate architectural forms and rapid construction with reduced material waste, enhancing both creativity and sustainability. Your projects benefit from improved precision and durability, making custom, eco-friendly homes more accessible than ever before.

Key Benefits of Using 3D-Printed Concrete Elements

3D-printed concrete elements in home design offer unparalleled precision and customization, enabling architects to create complex geometries that traditional methods cannot achieve. This technology significantly reduces construction time and labor costs while minimizing material waste, promoting sustainability and efficiency. Enhanced durability and strength of 3D-printed concrete ensure long-lasting structural integrity, benefiting both residential aesthetics and functional performance.

How Parametric Design Transforms Home Architecture

Parametric design revolutionizes home architecture by enabling dynamic customization through algorithm-driven models that optimize space, light, and structural efficiency. Your home evolves with precise adjustments based on environmental data and personal preferences, ensuring innovative aesthetics combined with functional living spaces. This technology streamlines complex design processes, reducing construction time and costs while maximizing architectural creativity.

Workflow: From Parametric Model to 3D-Printed Structure

The workflow from parametric model to 3D-printed structure involves generating a detailed digital design using parametric tools that define geometry through adjustable parameters, enabling precise customization and optimization. This model is then converted into a compatible file format, such as STL, which guides the 3D printer to construct accurate, complex architectural components layer by layer, streamlining the fabrication process and reducing material waste.

Material Innovation: Properties of 3D-Printed Concrete

3D-printed concrete offers unparalleled customization, combining high compressive strength and rapid curing times to enhance structural integrity and design flexibility. Your home design benefits from this material innovation by enabling complex architectural forms with reduced material waste and increased sustainability.

Case Studies: Successful Parametric 3D-Printed Homes

Case studies of successful parametric 3D-printed homes demonstrate innovative use of customizable algorithms that optimize structural efficiency and material usage, resulting in sustainable and cost-effective housing solutions. Projects like the ICON Vulcan and Apis Cor's residential units showcase rapid construction times and complex geometric designs that traditional methods cannot achieve, highlighting the transformative potential of 3D printing in modern home design.

Challenges in Parametric 3D Concrete Printing

Parametric 3D concrete printing in home designing faces challenges such as material consistency, structural strength, and print speed, impacting overall build quality and time efficiency. Ensuring precise control over the concrete mix and printer calibration is critical to prevent defects like layer delamination and cracking. Addressing scalability for large-scale residential projects requires advanced software algorithms and robust hardware integration to maintain design accuracy and structural integrity.

Sustainable Features in Parametric 3D-Printed Homes

Parametric 3D-printed homes integrate sustainable features such as energy-efficient insulation materials and optimized building geometries to reduce waste and minimize environmental impact. Advanced design algorithms enable precise material usage, lowering carbon footprints through reduced construction emissions and resource conservation. Renewable energy integration and passive solar design further enhance the eco-friendly performance of these innovative housing solutions.

Future Trends in 3D-Printed Parametric Home Design

3D-printed parametric home design is revolutionizing architecture by enabling highly customizable and sustainable structures tailored to individual needs. Advances in materials science and AI-driven design algorithms allow for faster construction, reduced waste, and enhanced energy efficiency in your future home. This innovative approach integrates smart technology and adaptive features, setting new standards for personalized living environments.

homedesy.com

homedesy.com